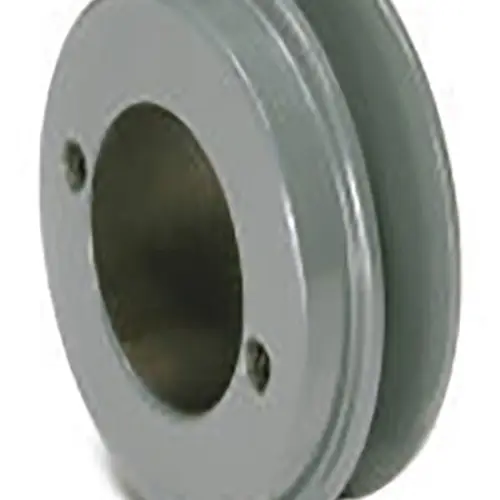

China Custom V-Ribbed Deflection Guide Belt Idler Pulley for BMW Mini Air Compressor Parts

Product Description

The VKM36339 V-Ribbed Deflection Guide Belt Idler Pulley 11287800333 7800333 is a high-quality aftermarket part suitable for BMW Mini air compressor systems. This pulley is designed to effectively guide and maintain the tension of the V-ribbed belt, ensuring optimal performance and longevity of the compressor.

Key Features:

- Part Number: VKM36339

- Interchangeable with multiple OEM and aftermarket part numbers

- Designed for BMW Mini air compressor systems

- Ensures proper tension and guidance of the V-ribbed belt

- Durable construction for long-lasting performance

Applicable Car Models

| Vehicle Models | Active Years | Engine | Displacement | Power | Cons.Type |

|---|---|---|---|---|---|

| BMW 1 (E81) 116 d | 2008-2011 | N47 D20 A, N47 D20 C | 1995 | 85 | Hatchback |

| BMW 1 (E87) 116 d | 2011-2011 | N47 D20 C | 1995 | 66 | Hatchback |

| BMW 1 Convertible (E88) 118 d | 2008-2013 | N47 D20 A, N47 D20 C | 1995 | 105 | Convertible |

| BMW 1 Coupe (E82) 118 d | 2009-2013 | N47 D20 C | 1995 | 100 | Coupe |

| BMW 3 (E90) 316 d | 2009-2011 | N47 D20 C | 1995 | 85 | Saloon |

| BMW 5 (F10) 525 d | 2011-2011 | N57 D30 A | 2993 | 150 | Saloon |

| BMW 7 (F01, F02, F03, F04) 730 d | 2008-2015 | N57 D30 A | 2993 | 155 | Saloon |

Packaging & Shipping

| Packaging Details | 1 piece in a single box 30 boxes in a carton 40 cartons in a pallet |

| Nearest Port | ZheJiang or HangZhou |

| Lead Time | For stock parts: 1-5 days If no stock parts: <500 pcs: 15-30 days >=500 pcs: to be negotiated. |

Our Services

Our company specializes in supplying a wide range of high-quality industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. With over 20 years of experience, we are committed to providing excellent quality control and customer satisfaction.

We offer OEM service and accept customer labels, allowing for customization based on drawings or samples. Our team is dedicated to providing prompt responses and exceptional customer service.

Frequently Asked Questions (FAQ)

1. How do you ensure the quality of your products?

We maintain strict quality control measures to ensure the superior quality of our products. Each item undergoes thorough testing before delivery to guarantee its performance and reliability.

2. Can I customize the products according to my specific requirements?

Yes, we welcome customization based on your drawings or samples. Our team will work closely with you to develop products that meet your exact specifications.

3. What are your accepted payment terms?

We require a 30% deposit via T/T (Bank Transfer) and the remaining 70% before delivery. Once the balance payment is made, we will provide you with photos of the products and packaging for your confirmation.

4. What are your terms of delivery?

We offer various delivery terms, including EXW, FOB, CFR, CIF, and DDU. Please let us know your preferred delivery method, and we will arrange the shipment accordingly.

5. How can I contact your company for further inquiries?

For any further inquiries or questions, please feel free to reach out to us. We are available 24/7 and will be more than happy to assist you.

Disclaimer: The content of this page is sourced from the Internet and is provided for reference purposes only. It is important to note that our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are designed to be compatible with the original spare parts and can be perfectly adapted. If you require original spare parts, please contact the original manufacturer or supplier.

Performance Characteristics of Mini Pulley

Mini pulleys are known for their exceptional performance characteristics. Here, we will explore the key points that make them stand out:

1. High Durability: Mini pulleys are designed to withstand heavy loads and harsh environments. They are made from robust materials that ensure long-lasting performance.

2. Smooth Operation: These pulleys offer seamless rotation, resulting in smooth and efficient functioning. The reduced friction allows for enhanced performance and minimal wear and tear.

3. Compact Size: Mini pulleys are specifically designed to be compact, making them suitable for applications where space is limited. Their small size does not compromise their functionality.

4. Versatile Applications: Mini pulleys can be used in various fields and industries. Their adaptability makes them suitable for DIY projects, medical devices, automotive components, office equipment, fitness equipment, and more.

Types and Characteristics of Mini Pulley

Mini pulleys come in different types, each with its own set of characteristics. Let’s explore some common types:

1. Single Groove Pulley: This type of pulley has a single groove for the belt or rope to run smoothly. It is ideal for applications that require a simple setup.

2. Double Groove Pulley: As the name suggests, this pulley has two grooves, allowing for multiple belts or ropes to be used simultaneously. It provides increased stability and load distribution.

3. Plastic Pulley: Made from high-quality plastic materials, these pulleys offer excellent resistance to corrosion and wear. They are lightweight and cost-effective.

4. Metal Pulley: Metal pulleys are known for their durability and strength. They can withstand heavy loads and high temperatures, making them suitable for demanding applications.

Advantages of Mini Pulley Made of Different Materials

The material used in the construction of mini pulleys greatly impacts their performance. Let’s explore the advantages of pulleys made from different materials:

1. Plastic Pulleys: These pulleys are lightweight, corrosion-resistant, and cost-effective. They are suitable for applications where weight and cost are a concern.

2. Aluminum Pulleys: Pulleys made from aluminum offer a good balance between strength and weight. They are commonly used in applications requiring high precision and speed.

3. Stainless Steel Pulleys: Stainless steel pulleys provide excellent durability and resistance to corrosion. They are ideal for applications where hygiene and cleanliness are crucial.

4. Brass Pulleys: Brass pulleys offer superior conductivity and are often used in applications that require electrical conductivity, such as in certain medical devices.

Application of Mini Pulley

Mini pulleys find extensive use in various fields due to their versatility. Let’s explore some key applications:

1. DIY Projects: Mini pulleys are commonly used in DIY projects, such as building small machines or mechanisms. Their compact size and reliable performance make them an ideal choice.

2. Medical Devices: Mini pulleys play a vital role in various medical devices, including surgical equipment and diagnostic instruments. Their precise and smooth operation is critical in these applications.

3. Automotive Components: Mini pulleys are used in automotive components, such as belt-driven systems and engine accessories. They ensure efficient power transmission and reliable performance.

4. Office Equipment: Mini pulleys are found in office equipment like printers and copiers. They contribute to the smooth movement of paper and other components, ensuring proper functionality.

5. Fitness Equipment: Mini pulleys are widely used in fitness equipment, such as treadmills and weight machines. They enable smooth and controlled movement, enhancing the overall exercise experience.

Future Development and Opportunities

The future of mini pulley products looks promising, with several development trends and opportunities on the horizon. Here are some key aspects to consider:

1. Technological Advancements: Advancements in materials and manufacturing techniques will lead to the development of more efficient and durable mini pulleys.

2. Growing Industries: As industries like healthcare, automotive, and DIY continue to grow, the demand for mini pulleys will also increase, creating new opportunities for manufacturers and suppliers.

3. Customization: The ability to offer customized mini pulleys based on specific requirements will be a significant advantage for manufacturers, catering to unique applications and needs.

4. Increased Automation: With the rise of automation in various industries, mini pulleys will play a crucial role in ensuring smooth and precise movement in automated systems.

How to Choose a Suitable Mini Pulley

Choosing the right mini pulley is essential to ensure optimal performance. Consider the following aspects:

1. Load Capacity: Determine the maximum load the pulley needs to handle and choose a pulley capable of handling that load without strain.

2. Material: Select the material based on the specific application requirements, considering factors such as corrosion resistance, conductivity, and strength.

3. Diameter and Size: Consider the available space and the required belt or rope size to determine the appropriate diameter and size of the mini pulley.

4. Type of Pulley: Choose the type of pulley based on the specific needs of the application, such as single groove or double groove pulleys.

5. Bore Size: Ensure that the bore size of the pulley matches the shaft or spindle it will be mounted on to ensure a secure fit.

Conclusion

Mini pulleys offer exceptional performance characteristics, making them invaluable in various applications. Their durability, compact size, and versatility make them a popular choice in DIY projects, medical devices, automotive components, office equipment, fitness equipment, and more. As the industry continues to evolve, mini pulleys will play a significant role in driving innovation and meeting the growing demand for reliable and efficient mechanical systems.

Author: Dream